Quantifying Sustainability: CHUGG’s Yearly Carbon Reduction

By processing approx 75 kgs of food waste per day, CHUGG helps avoid about 68.4 tonnes of carbon emissions annually.

Equivalent to

3,250 Trees Planted

15 Cars

off the road

46 households electricity use

1,200 LPG Cylinders

Together, we’ve made a real difference!

Till date, AVRIS has prevented 1839875 kgs of food waste from ending up in landfills

cutting down 4599688 kgs of carbon emissions and paving the way for a cleaner, greener future.

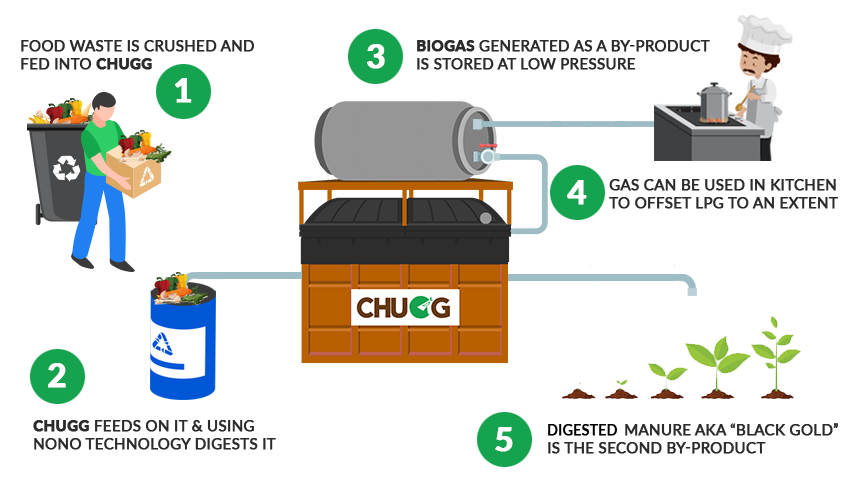

Process Flow

Food Waste Treatment System

Innovative Food Waste Treatment System In India

CHUGG is an innovative food waste treatment system which treats your food waste at source and save you from the hassle of disposal

Hey Industries, Hoteliers, Restaurants, Large Kitchens, Apartments & Institutions… CHUGG is here!

Did you know

Benefits Of CHUGG

Converts waste to energy

Eureka! CHUGG converts food waste into gas which can be used to produce heat/electricity.

State of the art Nano Technology

It is Modular, compact & occupies minimum space. You can install additional units as and when your food waste increases. Processes food waste at a faster rate using biological treatment.

Minimum Human Intervention

It is very easy to operate. CHUGG is automated and highly user friendly, needing an operation time of 15 – 30 minutes a day.

Pays for itself as readily usable by products

CHUGG produces gas & manure which can offset your investment.

Easy to Install

No civil work required. Easy to install & relocate

How is CHUGG different from other systems?

| Parameters | CHUGG 75 | Organic Waste Converter | Bin Composting |

|---|---|---|---|

| Process | Anaerobic digestion | Incineration | Aerobic |

| Power required | 1 Unit / day | Power Intensive | No |

| Plant | Portable- Modular- occupying lesser foot space | Portable- Modular | Portable- Modular |

| Plant / process positioning | Inside / Outside Kitchen | Inside / Outside | Outside |

| Food Crusher | Recommended | Recommended | No |

| Odour | No | Yes, as machine needs to opened daily | Yes, as bin need to be stirred constantly |

| Digestion time | 15-20 days | No natural digestion | 3-4 months |

| Operation cost per month (Electricity) in Rs | Nil | 25000 | 8000 |

| Additives, chemicals | No | Saw dust | Microbes |

| By product | Biogas & digested fertilizer. | Neutral mass needing further disposal | Fertilizer |

| Discharge | Nil | Water–which needs to be drained | CO2 and Water–which needs to be drained |

| Environment Footprint | Carbon positive as it does not use energy & generates biogas for cooking and bio manure. | Carbon Negative uses power & resultant discharge needs to be treated. | Reduces Carbon foot print |

| ROI | 18-26 months | Extended | Extended |

CHUGG Variants

Dimensions

3’10” X 3’10” X 6’

1150mm x 1150mm x 1800mm

Dimensions

3’10” X 6’6” X 6’

1150mm x 1950mm x 1800mm